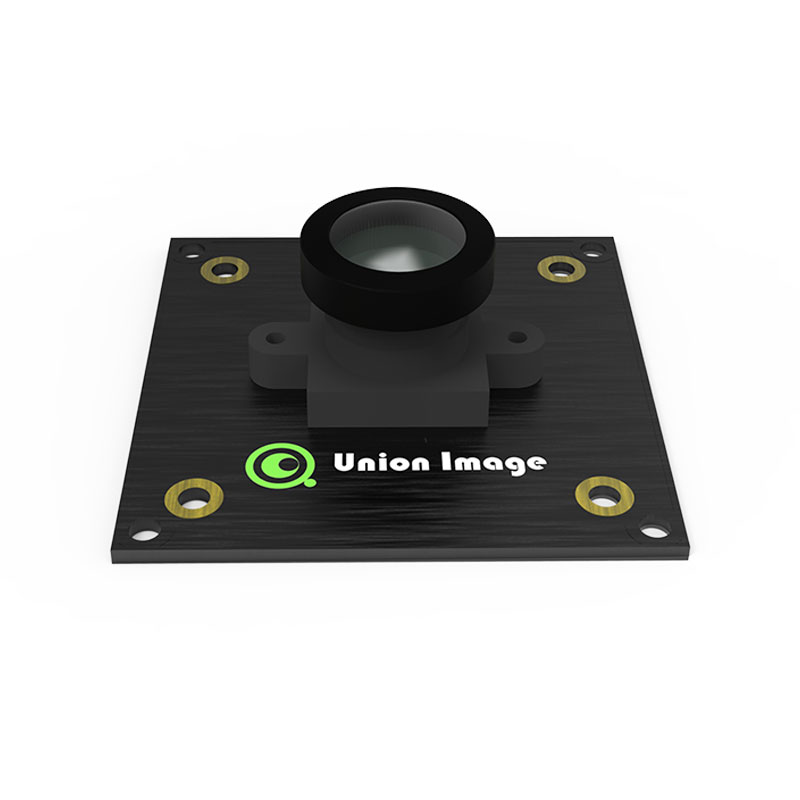

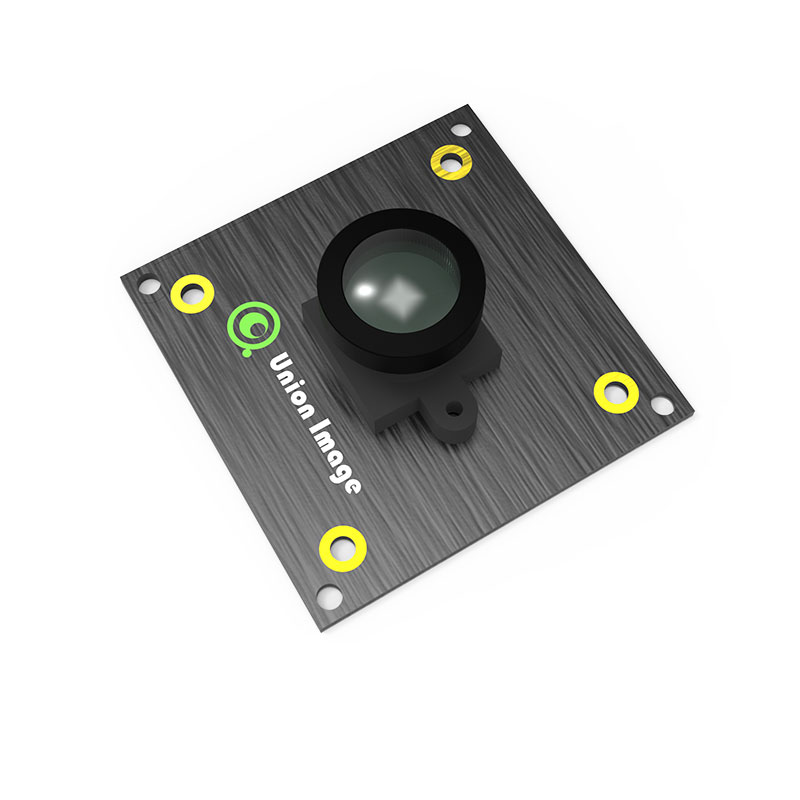

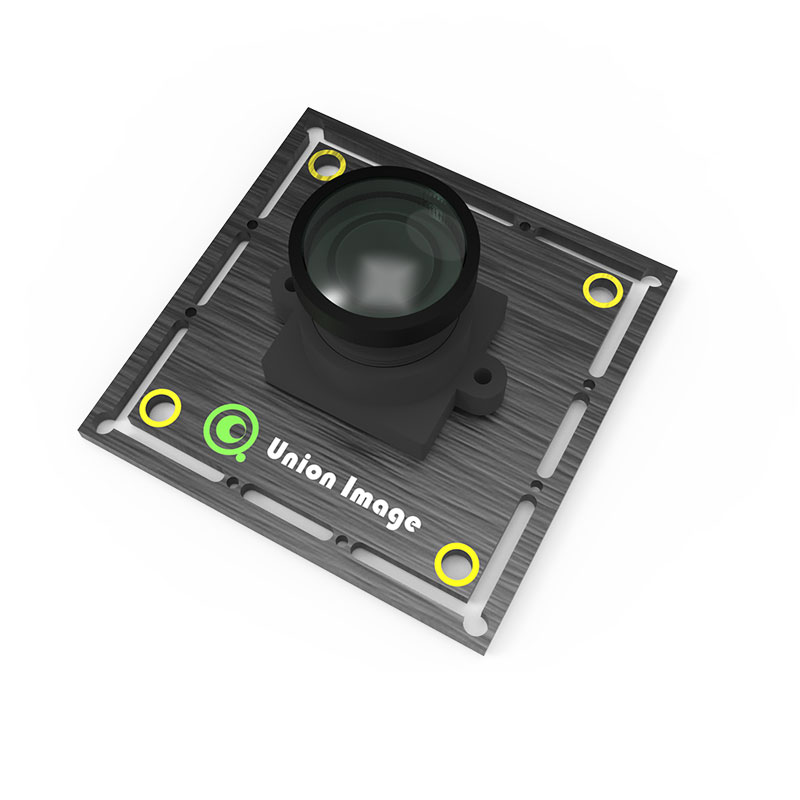

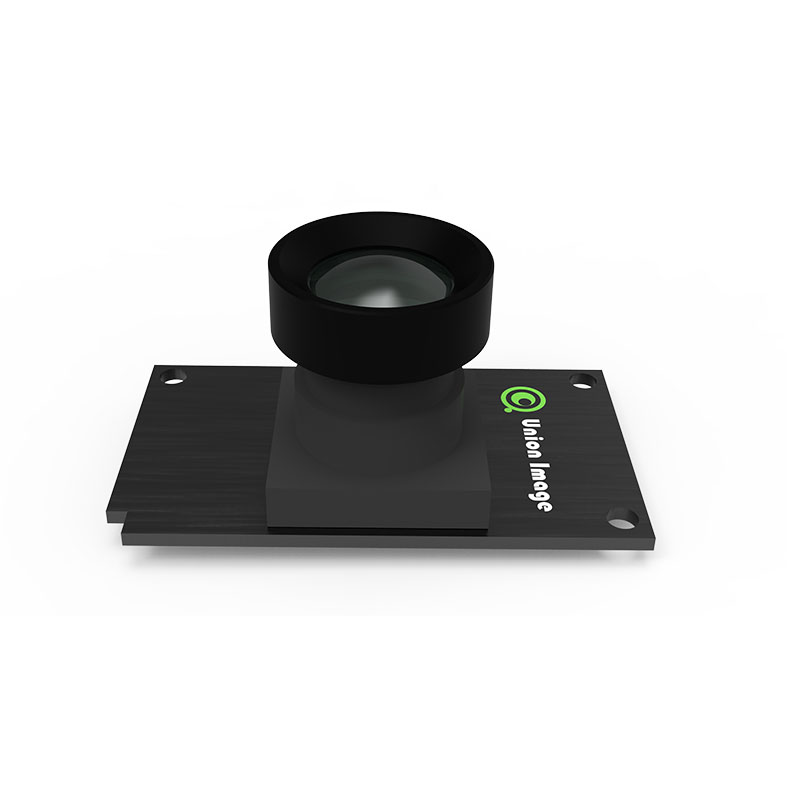

| Chip type | SC230AI |

| Array size | 1928H x 1088V |

| AVDD (Analog Voltage) | (Typ. 2.8V) |

| DVDD (Digital Voltage) | (Typ. 1.5V) |

| DOVDD (IO Voltage) | (Typ. 1.8V) |

| Sensor CRA | 15° |

| Sensor IIC Address | - |

| Pixel Size | 2.9um×2.9um |

| EFL (Effective Focal Length) | 2.28mm |

| F/NO (Aperture) | 2.2?% |

| View angle | D178.4°H150.2°V80.4° |

| TV - Distortion | < -30.1% |

| Focusing range | TBD |

| Chief Ray Angle | 13° |

| COMPOSITION | 2G + 4P |

| FILTER | 650nm |

Visualization and Monitoring of the CookingProcess

Real -time video streaming:

Hightemperature resistant cameras(operating temperature s 300°C)recordvideos, which can be remotely viewed via amobile App.Al algorithms are used toeliminate reflections from glass doors andinterference from water vapor.

Time lapse photography function:

Automatically generates snapshots of theentire cooking process, facilitatingthereview of baking results(such astheexpansion process of bread).

Ingredient Recognition and Recommendation:Scan ingredient barcodes/image recognition(e.8,ResNet50 model)to recommend theoptimal cooking mode (temperature/time/humidity).

Automatic Parameter Adjustment

Dyamically adjust the intensity of hot - aircirculation: Optimize the airflow path basedon the heat distribution map captured by thecamera.

Humidity control: The timing of steaminjection is linked to the dryness of the foodsurface monitored by the camera.